DJ wavy guard belt conveyor

| Item No.: | IFA-IQN489145 |

DJ wavy guard belt conveyor

Product features:

DJ wavy guard belt conveyor adopts s-shaped wave shape guard height to choose different transverse diaphragm type, diaphragm type is T type, C type, Tc type, Ts type and Tcs type etc. Diaphragm

according to the following requirements:

1、 For small angle (0 < α < 18) is generally not used diaphragm

2、 For large angle (18 < α < 40) by using T type diaphragm;

3、 For large angle (40 < α < 60) by using C type diaphragm;

4、 For large angle (60 < α < 90) using Tc or Tcs type diaphragm;

5、 When the cross baffle height is greater than or equal to 280mm using the Ts or Tcs type diaphragm

DJ wavy guard belt conveyor uses Y series motor, ZQ, or DBY and DCY series reducer drive device, according to the needs of domestic hydraulic coupling and the brake. Electric drum is being used when the driver power is less than 55KW.

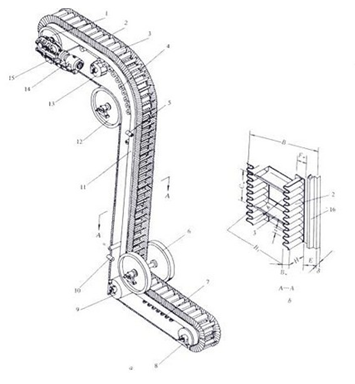

1- transmission drum

2- corrugated edge belt;

3- diaphragm

4- turning roller

5- gear wheel;

6- haul catch wheel;

7- pinto roller;

8- the tail drum

9- redirection roller

10- back with retaining wheel;

11- baseband empty edge

12- back to the turning drum;

13- vibrator

14- drive (motor and gear box)

15- frame (the unpainted);

16- flange

B1-effective medium bandwidth;

Bw- sidewall belt width;

Fw- sidewall belt width;

H- sidewall belt high;

h- transverse diaphragm;

B- The base bandwidth;

E- empty edge width

O- the base bandwidth;

t-wave distance

Cw- diaphragm spacing

Main technical parameters of DJ wavy guard belt conveyor

|

The base bandwidth(mm) |

Flange height(mm) |

Diaphragm height(mm) |

Belt speed(m/s) |

Nominal angle(°) |

||||

|

500 |

80 |

100 |

120 |

75 |

90 |

110 |

0.8 1.0 1.25 1.6 2.0 2.5 3.15 |

0~30 35~40 45~50 55~60 65~70 75~80 85~90 |

|

650 |

100 |

120 |

160 |

90 |

110 |

150 |

||

|

800 |

120 |

160 |

200 |

110 |

150 |

180 |

||

|

1000 |

160 |

200 |

240 |

300 |

180 |

220 |

||

|

1200 |

200 |

240 |

300 |

180 |

220 |

280 |

||

|

1400 |

240 |

300 |

400 |

220 |

280 |

360 |

||